Research recently commissioned by leading power tools manufacturer, FEIN, has revealed more than two-thirds of metalworkers would like to advance their current ways of working by introducing new technology into their role, improving the overall productivity of the sector. While 37% admit their company isn’t doing anything to plan for a successful future.

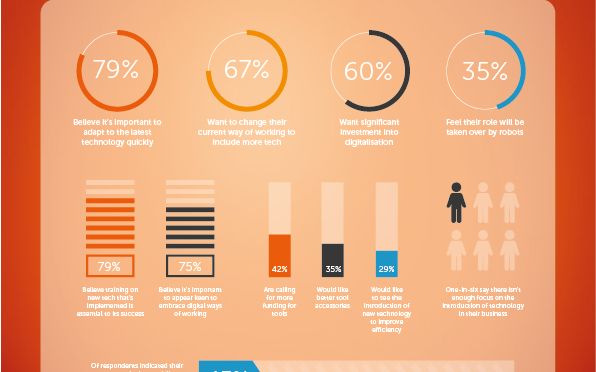

The data also uncovered 29% believe new technology would improve the efficiency of the industry, with more streamlined processes likely to inform the decision-making process of new business for years to come. While 60% believe it’s important their company is investing significant amounts into digitalisation and half say it’s imperative their company has software-enabled intelligent machines rather than stand-alone hardware.

“Technology and innovation have been causing a buzz across the production sector for several years now. Traditionally slow to adapt compared to other industries, there has been a great period of change emerging in the metalworking industry when it comes to innovation and transformation recently,” comments Andy Mills, managing director, FEIN UK. “However, it’s clear there still needs to be strong investment in this area, with one-in-six stating there isn’t enough focus on the introduction of technology in their business.”

On evolving and adapting to change, the research found that:

- 79% say it’s important to adapt to the latest technology quickly with the talent and projects which can come off the back of these adaptions, signalling it’s not just investment in new technology that needs focus from the metalworking sector

- 64% claim they want the specialists who supply machines or tools to provide ongoing training and support into how to effectively use any new solution which is brought into the business

- 65% would like better training to improve their company’s overall efficiency

- 63% admit they don't know what their company is doing to plan for a successful future

The research further outlined that over half of those surveyed believe companies in the metalworking sector had to be seen to be moving quickly, adapting to change and transformation, in order to gain the advantage over their competitors.

“It’s clear digital methods and technology will play a pivotal role in futureproofing the metalworking sector and will be integral if the UK is to remain a global industry leader in the space. Those who are embracing new technology will have the upper-hand when it comes to recruiting the best talent and securing the best work.

“There does however need to be increased awareness that integrating any new technology needs to be accompanied by significant training before they can be properly adopted. Without this, the level of time and budget wasted without proper insight into the way it works will heavily impact the return on investment. For this very reason, we recently adapted our global strategy to provide more hands on training for our tools, ensuring end users are utilising them as effectively as possible,” concludes Andy.

To find out more and to download the full ‘future of the metalworking sector’ report, visit https://www.fein.com/en_uk/knowledge/metalworking-sector-report/.